When two companies that share a passion for precision come together, the results speak for themselves. Arc-Zone recently partnered with SunTiger Industries to support their aerospace welding tests under the AWS D17.1 standard. The collaboration brought together cutting-edge gas purification technology and Suntiger’s disciplined approach to maintaining NADCAP-compliant welding environments — and the outcome was as clean and controlled as a weld bead under a perfect arc.

The Arc-Zone x SunTiger Collaboration

Arc-Zone teamed up with SunTiger Industries by contributing one of our gas purification systems for their high-standard aerospace test series. In exchange, we were given a rare opportunity to film and document their entire process for educational purposes.

As Trevor Godinez from SunTiger explained, “Arc-Zone and SunTiger have collaborated together to really dial in a gas purification system like you’ve never seen. Basically giving us the purest gas so that we have the cleanest outcome for stainless steel, aluminum, titanium — whatever metals we’re working with in the aerospace industry.”

It was a hands-on exchange of innovation: SunTiger gained an ultra-clean, consistent gas flow, while Arc-Zone gained a glimpse into what a truly controlled aerospace weld environment looks like.

Inside the Aerospace Welding Process

Walking through Suntiger’s dedicated welding lab was an education in excellence. Every detail — from temperature regulation to ventilation — is designed to ensure weld integrity under AWS D17.1 specifications.

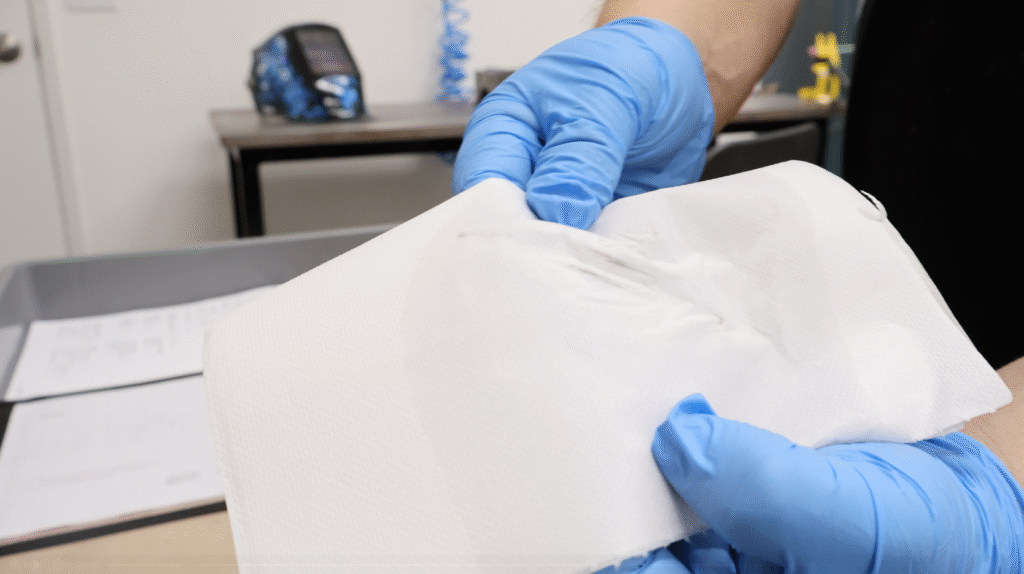

The process starts long before the torch is lit. Each part is carefully cleaned with high-grade acetone, removing any trace of dust, oil, or debris that could compromise the weld. “Even new filler rod can have debris or residue on it,” Trevor explained. “We clean everything before it even gets close to the weld table.”

The next critical step: tungsten preparation. Properly sharpening the tungsten ensures a stable arc and a clean, consistent weld pool. Once the electrode is ready, welders turn to the filler material, stored in a climate-controlled container that maintains the exact humidity and temperature required under NADCAP regulations. Only certified welders have access to this area, ensuring absolute traceability and control.

The Importance of Cleanliness and Precision

From the outside, welding might look like fire and metal — but in aerospace, it’s about control and cleanliness. SunTiger’s process reflects that mindset at every stage. Proper cleaning, tungsten preparation, gas purity, and environmental consistency all play a part in achieving perfect results.

As Trevor put it best, “When you combine clean materials, clean gas, and the right setup — that’s when you see what aerospace welding is really about.”

It’s a reminder that behind every great weld is a disciplined process and a deep respect for the craft.

What We Learned from SunTiger Industries

Our time with SunTiger was more than just a filming session — it was an experience that reinforced why standards like AWS D17.1 and NADCAP compliance exist: to push the boundaries of quality and safety.

Seeing their level of organization, documentation, and attention to detail firsthand reminded us that precision isn’t just a goal — it’s a habit. SunTiger’s approach is setting a benchmark for how aerospace welding should be done, and we’re proud that Arc-Zone could play a small part in that process.

Conclusion

This collaboration underscored what true aerospace welding demands: consistency, documentation, and process control. By aligning Arc-Zone’s gas purification expertise with SunTiger’s NADCAP-level discipline, we demonstrated how the right partnership can achieve uncompromised quality. It’s partnerships like these that continue to advance the welding industry and inspire welders everywhere to elevate their standards.

“That’s the SunTiger way,” Trevor said — and after witnessing their process, we couldn’t agree more.

Watch the Collaboration

🎥 Watch the full video! Be on the look out in the next upcoming weeks to see when we drop the video of what went down in the lab! Make sure you are following us on all Social media platforms so you can stay up to date.